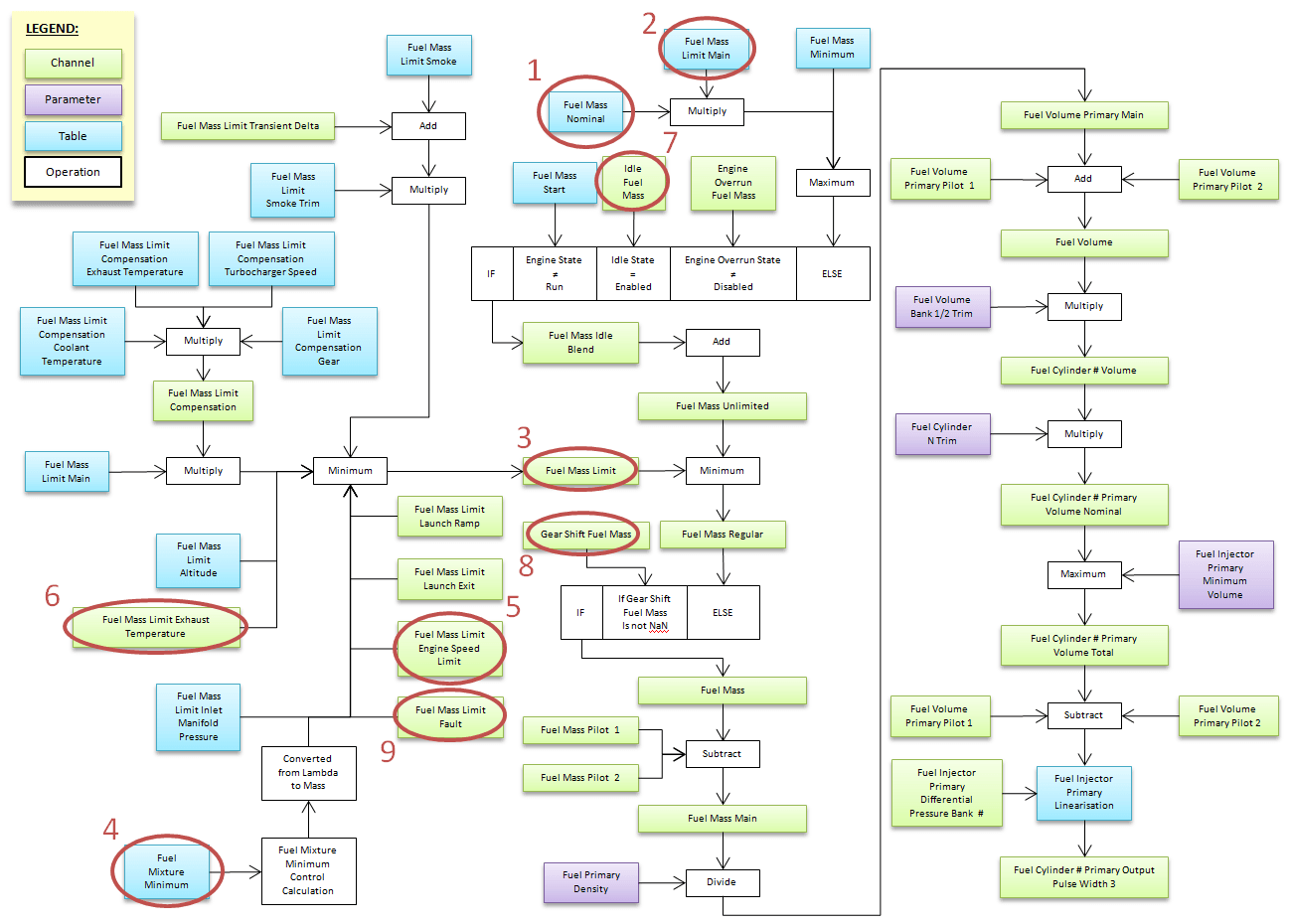

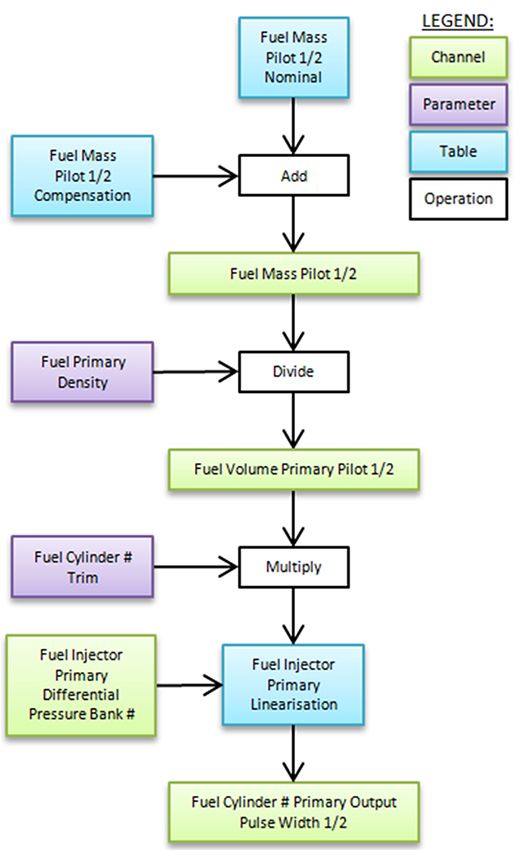

MoTeC's M1 GPR Diesel Package is a versatile and adaptable platform for the operation of diesel fuelled engines.

This Package has been designed for direct injection, common rail, turbo diesel engines, but can also be used for naturally aspirated diesel applications. Many features from MoTeC's petrol GPR Packages have been reproduced in this Package, providing a familiar feel for current GPR users.