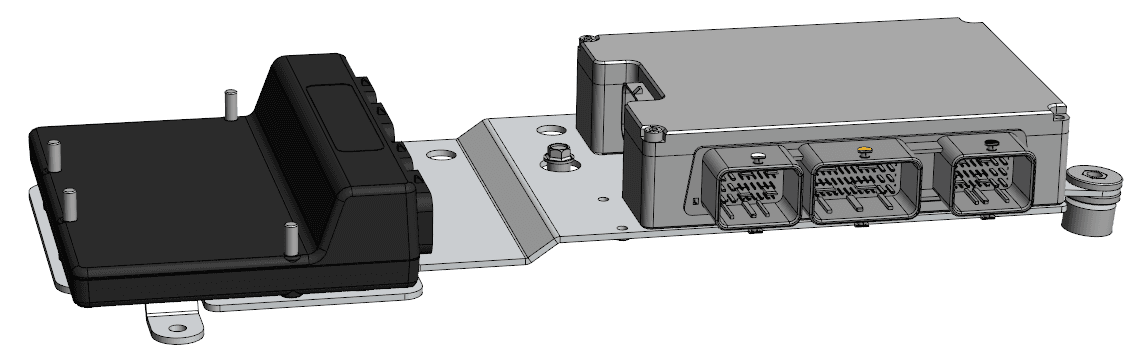

This Plug-In Kit is designed as a complete replacement for the factory OE (original equipment) ECU, using existing wiring, sensors and mounting hardware to deliver plug-in convenience with fully programmable control. The ruggedised M150 ECU is supplied with the Package preloaded, providing complete functionality for the Mercury Racing QC4V engine. The Package is based on MoTeC's GPR Package with additional features unique to this engine.

Along with dual drive-by-wire, fuel, ignition and dual turbocharger control, this Package adds knock control to the QC4V and also supports OE ECU features, including:

- Key start

- OE dash or MoTeC dash operation via OE CAN busses

- Trim up and trim down control

- Gear forward and reverse operation

- Trim tab position port and trim tab position starboard monitoring

- Stern leg position monitoring