The SVIM acquires data of the highest integrity for use in advanced chassis and suspension analysis. This versatile expander works in conjunction with Display Loggers C185, C187 or C1812 and Enclosed Logger L180 to facilitate the synchronised logging of high speed, high resolution inputs.

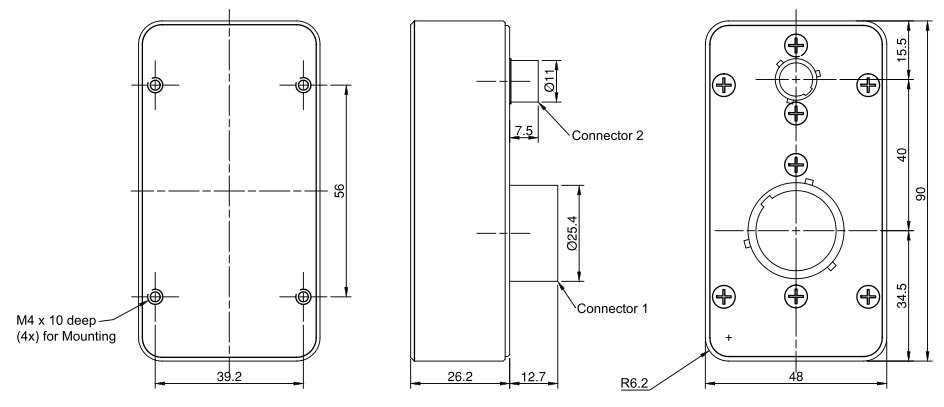

SVIMs are compact and can be located close to sensors, reducing the weight and complexity of wiring. When used in multiples, up to 200 sensor inputs are available.